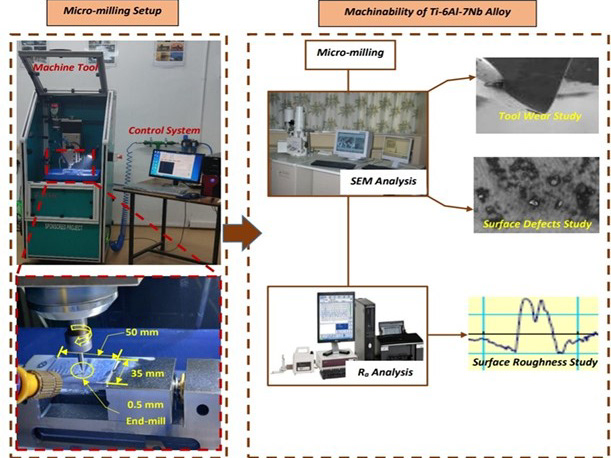

TNMG Carbide inserts are used for turning high-strength materials like aluminum and steel alloys, requiring high mechanical and thermal stability.

This study uses Finite Element Analysis to develop a new insert design, considering thrust force and heat effects. Improved design shows lower deformation and higher heat flow.

Rapid prototyping with 3D Printing was used to present design changes made in the tool.